Optimized workforce management

on the shopfloor

The mission is clear: The machines must run and be utilized efficiently. Workforce deployment must effectively ensure this even with fluctuating production volumes and a shortage of skilled workers. WorkforcePlus Production supports integrating workforce management into the daily production routine so intuitively and smoothly that planners have more time to focus on their core tasks, and shift schedules align well with employees.

The mission is clear: The machines must run and be utilized efficiently. Workforce deployment must effectively ensure this even with fluctuating production volumes and a shortage of skilled workers. WorkforcePlus Production supports integrating workforce management into the daily production routine so intuitively and smoothly that planners have more time to focus on their core tasks, and shift schedules align well with employees.

Lean production with lean workforce management

With WorkforcePlus Production, you not only significantly reduce the effort required for workforce planning, but also ensure optimal staffing for the manufacturing process while simultaneously placing increased focus on the needs of your employees.

With WorkforcePlus Production, you not only significantly reduce the effort required for workforce planning, but also ensure optimal staffing for the manufacturing process while simultaneously placing increased focus on the needs of your employees.

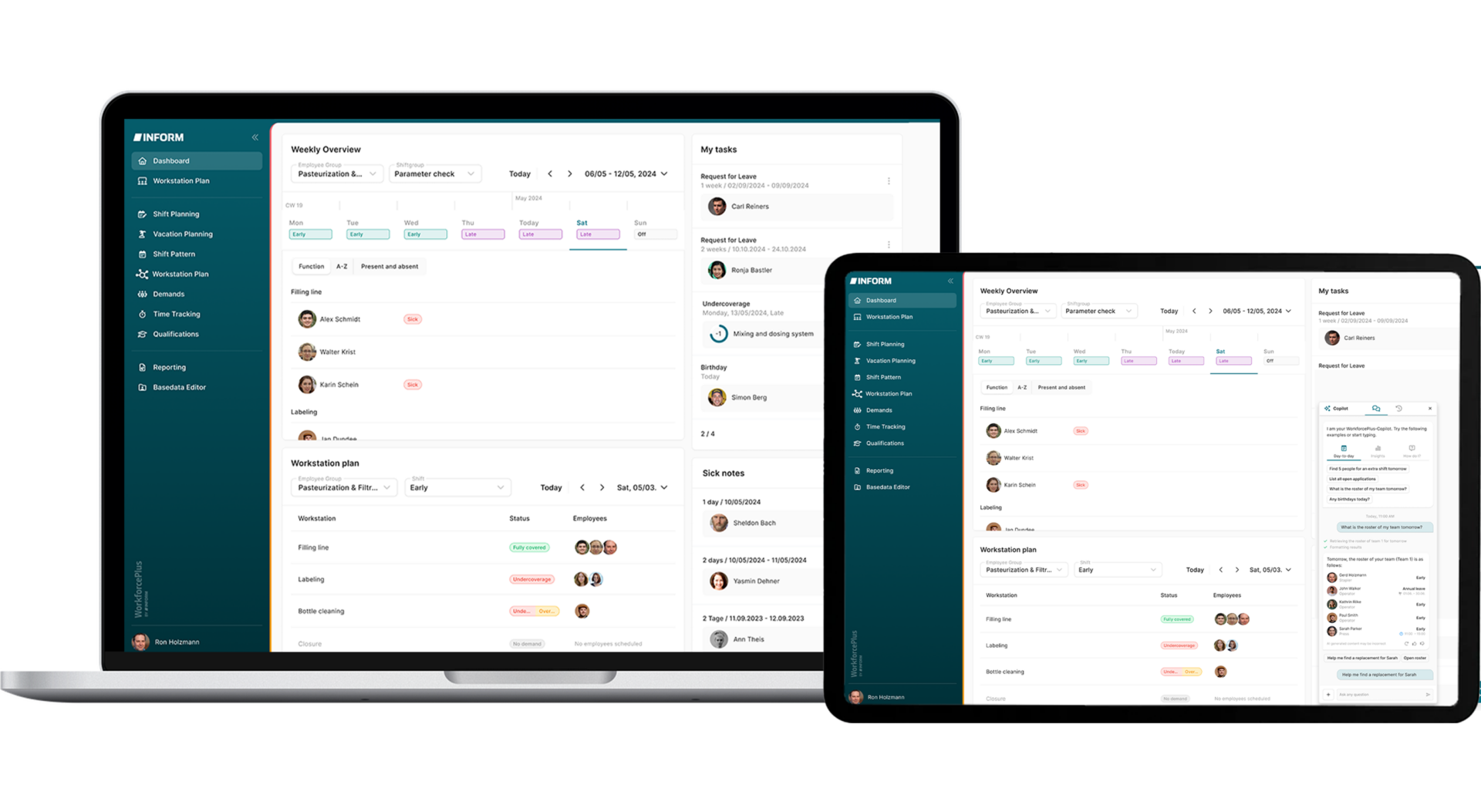

Responding quickly to short-term changes

Unexpected absences? Fluctuations in production volumes? Managing these short-term disruptions is seamless and efficient with a system providing real-time visibility into staffing gaps and production demands, allowing for quick adjustments with minimal disruption to workflow. Through intuitive dashboards and automated scheduling tools, supervisors can easily identify necessary changes and swiftly rearrange staff assignments to ensure optimal productivity.

Unexpected absences? Fluctuations in production volumes? Managing these short-term disruptions is seamless and efficient with a system providing real-time visibility into staffing gaps and production demands, allowing for quick adjustments with minimal disruption to workflow. Through intuitive dashboards and automated scheduling tools, supervisors can easily identify necessary changes and swiftly rearrange staff assignments to ensure optimal productivity.

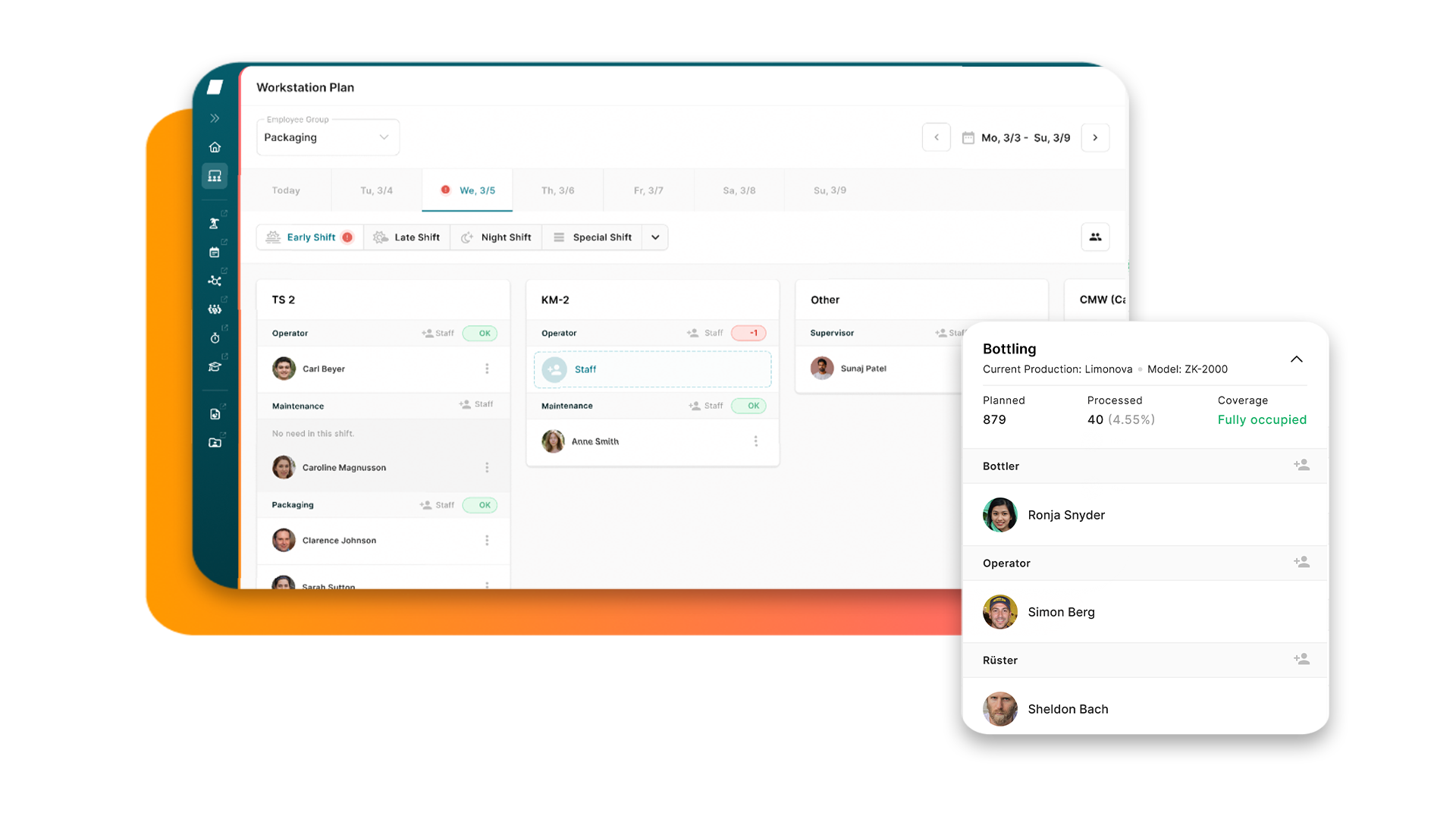

AI-optimized workforce management

Automatically generate appropriate shift schedules using AI, taking into account all operational requirements, laws, and agreements. In case of short-term changes in production planning, the schedule can be adjusted with minimal rearrangement through post-optimization.

Automatically generate appropriate shift schedules using AI, taking into account all operational requirements, laws, and agreements. In case of short-term changes in production planning, the schedule can be adjusted with minimal rearrangement through post-optimization.

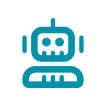

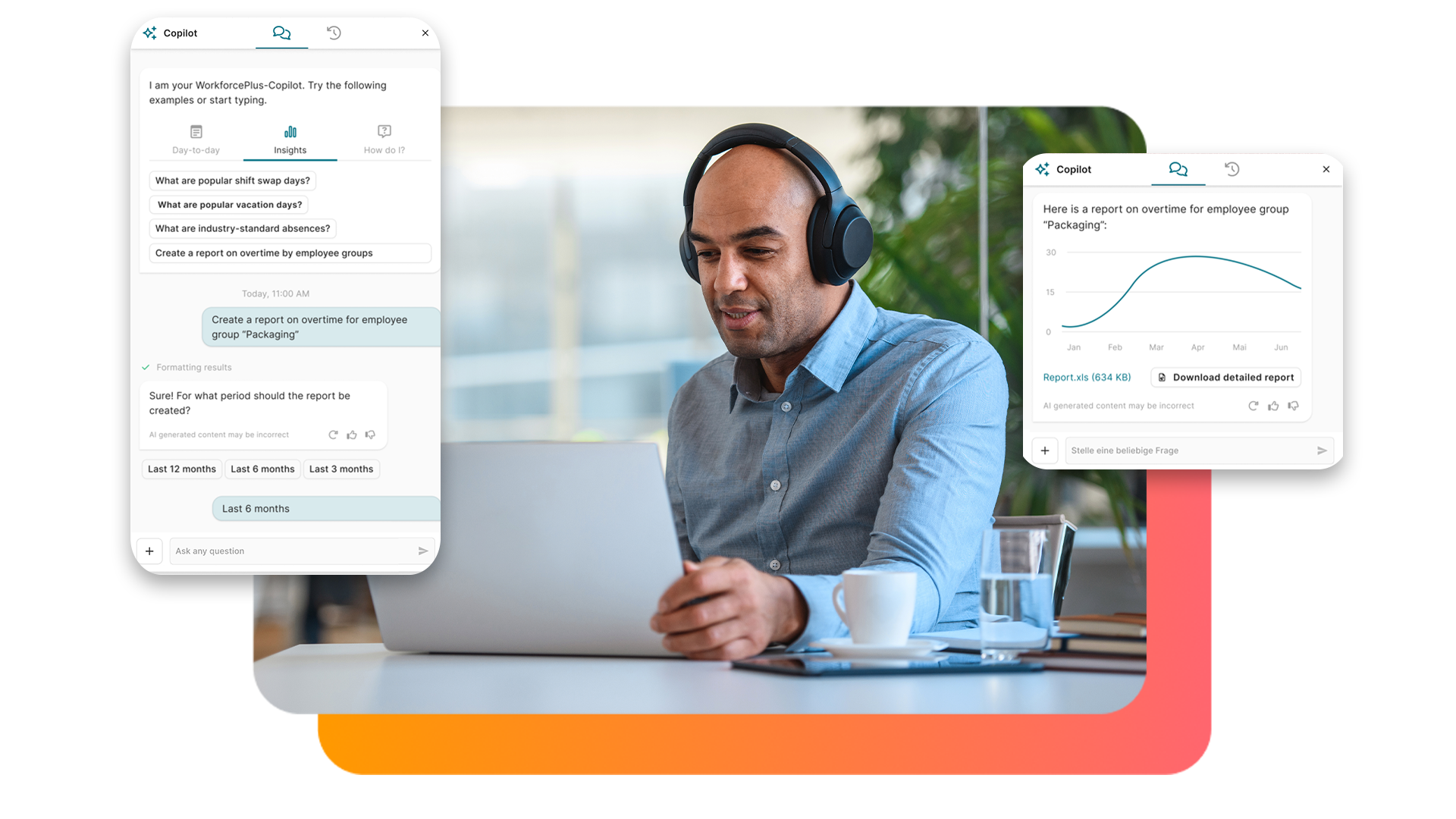

Copilot

Shift planning or changes via voice command? No problem! With a Copilot, interacting with the system is easy, and data can be aggregated, displayed, and analyzed. Less tedious research, less time spent, more time for what matters.

Shift planning or changes via voice command? No problem! With a Copilot, interacting with the system is easy, and data can be aggregated, displayed, and analyzed. Less tedious research, less time spent, more time for what matters.

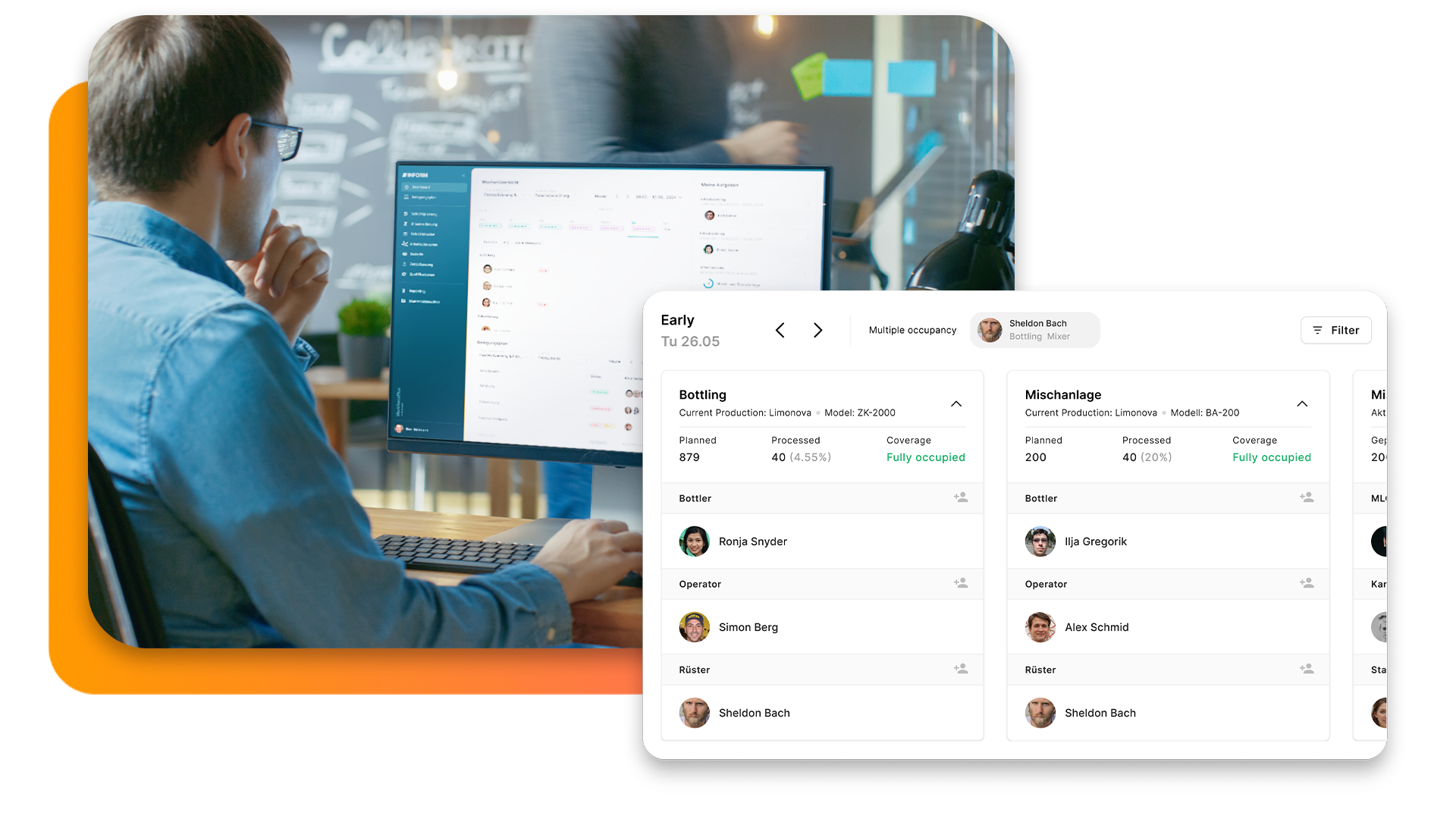

Multi-machine occupancy, qualification matrix, and more

Efficient manufacturing processes with optimal staffing. Generated plans align with defined production targets due to integrated qualification matrix, the ability for multi-machine occupancy, rule checks, demand balancing in terms of hours and production volumes, and further functionalities.

Efficient manufacturing processes with optimal staffing. Generated plans align with defined production targets due to integrated qualification matrix, the ability for multi-machine occupancy, rule checks, demand balancing in terms of hours and production volumes, and further functionalities.

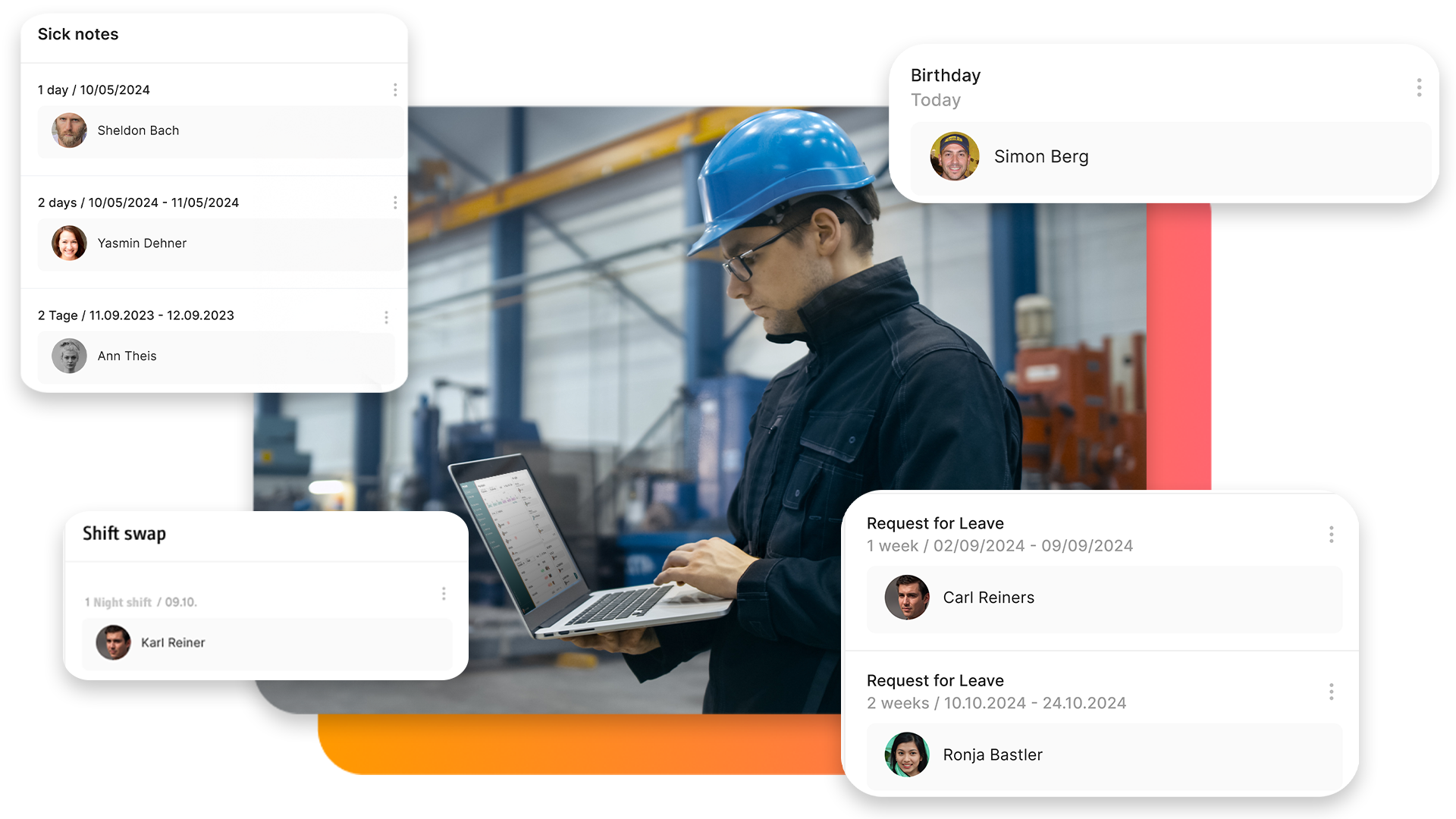

Communication and employee engagement

In the production environment, appreciation is becoming increasingly important. Individual needs of employees, such as shift exchanges or preferred shifts, can be scheduled without additional effort for the planner. Via employee self service, work schedules and vacation requests are transparently visible at all times, and planners are reminded of important information regarding their employees, such as company anniversaries, etc.

In the production environment, appreciation is becoming increasingly important. Individual needs of employees, such as shift exchanges or preferred shifts, can be scheduled without additional effort for the planner. Via employee self service, work schedules and vacation requests are transparently visible at all times, and planners are reminded of important information regarding their employees, such as company anniversaries, etc.

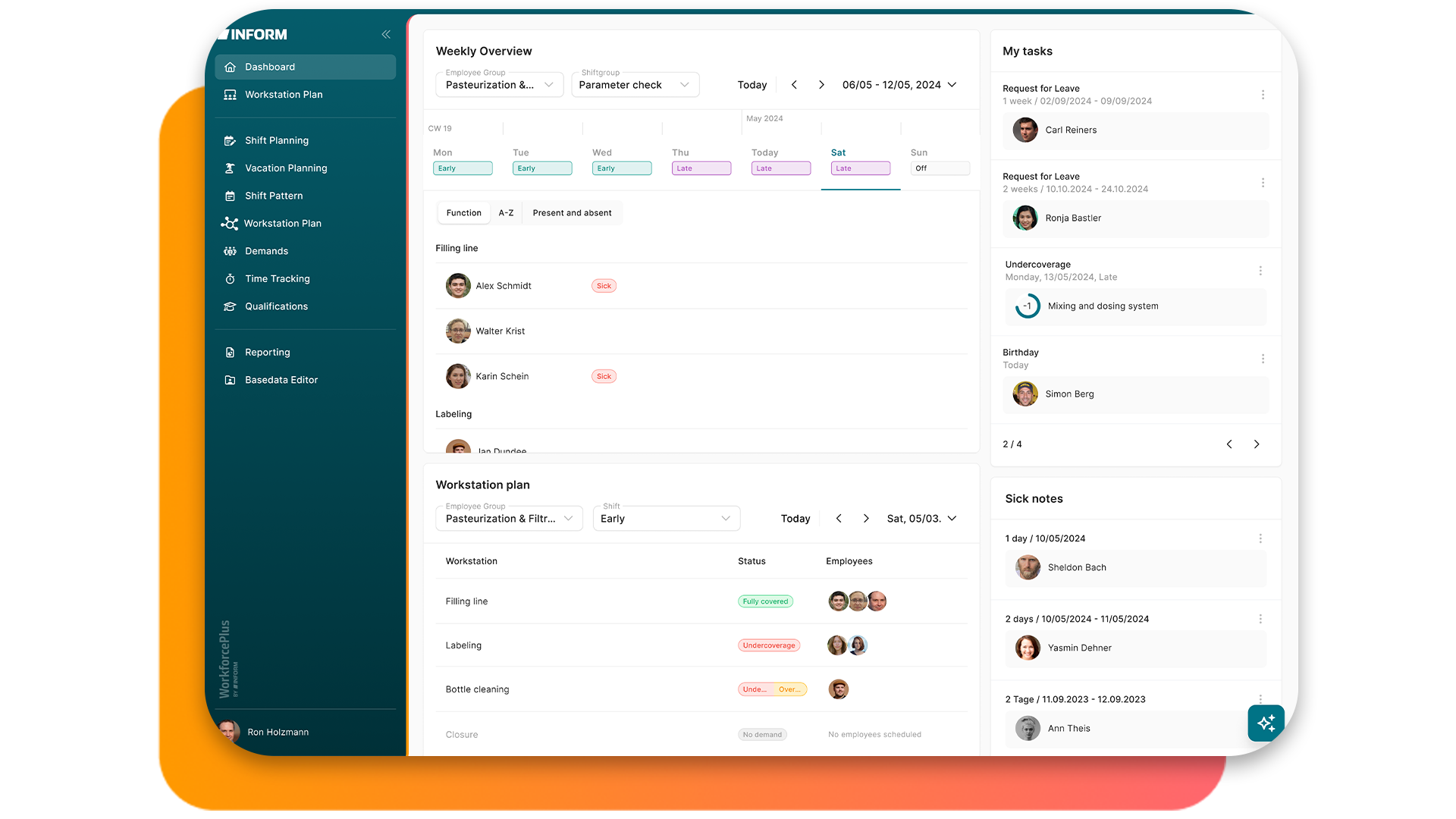

Simplified planning and intuitive operation

Having everything important at a glance – and seeing what is coming up soon. The dashboard makes it immediately clear which tasks need attention. No more searching, just less planning effort, quick adjustments, and efficient shift plans.

Having everything important at a glance – and seeing what is coming up soon. The dashboard makes it immediately clear which tasks need attention. No more searching, just less planning effort, quick adjustments, and efficient shift plans.

Quick seamless implementation

Quickly deployable and seamlessly integrated with the IT system landscape. All necessary information, such as staffing requirements, is incorporated into WorkforcePlus Production. Conversely, data is transferred to payroll systems for the relevant calculations.

Quickly deployable and seamlessly integrated with the IT system landscape. All necessary information, such as staffing requirements, is incorporated into WorkforcePlus Production. Conversely, data is transferred to payroll systems for the relevant calculations.

More information

Contact

For inquiries or more information, contact me:

Alina Schreier

Sales

For inquiries or more information, contact me:

Alina Schreier

Sales